Ensuring the safety of workers in factories and construction sites is a top priority for any business. Accidents in these environments can lead to serious injuries, financial losses, and legal consequences. One of the key ways to maintain safety is by equipping your site with proper safety equipment and conducting regular maintenance checks. This article provides a comprehensive safety equipment checklist and highlights essential practices like fire extinguisher refilling services.

1. Fire Extinguishers: Essential for Immediate Response

Fire safety is critical in both factories and construction sites due to the presence of flammable materials, heavy machinery, and electrical equipment. Fire extinguishers are the first line of defense in controlling small fires before they escalate.

Different types of fire extinguishers serve different purposes. CO2 fire extinguishers, for example, are effective against electrical fires, while water-based extinguishers are suitable for combustible materials like wood and paper. It is vital to maintain these extinguishers in proper working condition.

Regular refilling and maintenance are crucial. Searching for a fire extinguisher refilling service near me ensures your extinguishers are always functional. Many local providers also offer CO2 fire extinguisher refilling near me, which is specifically designed for electrical fire hazards. A trusted fire extinguisher refilling shop near me can check the pressure, refill the extinguishing agent, and certify the equipment for safety compliance.

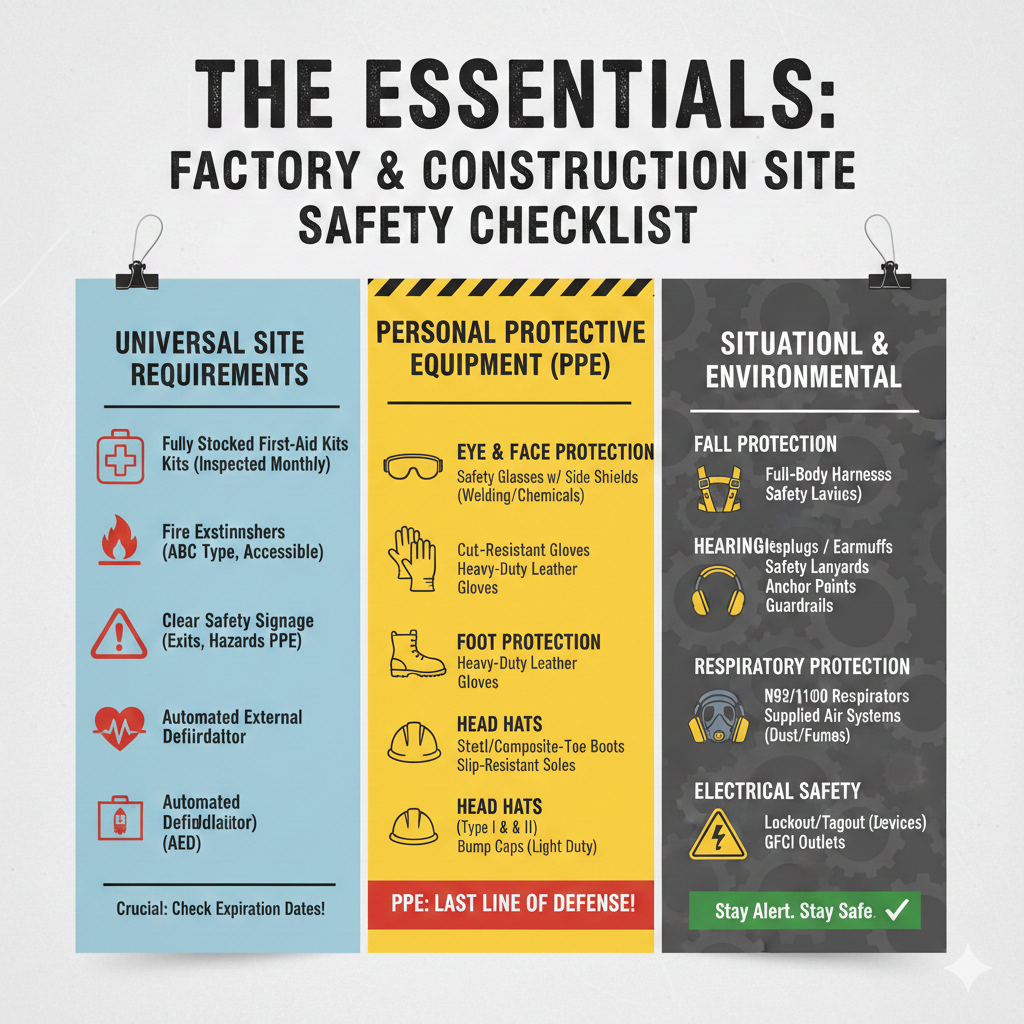

2. Personal Protective Equipment (PPE)

Workers in factories and construction sites are exposed to various hazards. Proper personal protective equipment (PPE) is essential to minimize risks. PPE includes:

-

Helmets to protect against head injuries from falling objects.

-

Safety goggles to shield eyes from sparks, dust, or chemical splashes.

-

Ear protection to prevent hearing loss in high-noise environments.

-

Gloves suitable for handling chemicals, machinery, or sharp objects.

-

Safety shoes with reinforced toes to avoid injuries from heavy materials.

Regular inspections of PPE are necessary to ensure they are in good condition. Damaged or worn-out equipment should be replaced immediately to maintain safety standards.

3. Emergency Signage and Exits

Factories and construction sites must have clear emergency signage indicating exits, fire extinguisher locations, and first aid stations. These signs should be visible, well-lit, and understood by all employees, including those with limited literacy. Emergency exits should remain unobstructed at all times to allow a quick evacuation during emergencies.

4. First Aid Kits and Medical Supplies

A well-stocked first aid kit is a necessity for handling minor injuries like cuts, burns, or sprains. Kits should include bandages, antiseptic wipes, burn creams, splints, and gloves. Regular audits of first aid kits help ensure all items are present, functional, and not expired. On larger sites, having a trained first aid responder or medical personnel can save lives in case of serious accidents.

5. Fire Safety Systems and Alarms

Beyond portable fire extinguishers, larger factories and construction sites should invest in comprehensive fire safety systems. These include smoke detectors, heat sensors, fire alarms, and sprinkler systems. Regular testing and maintenance of these systems are vital. Consulting with professionals and integrating services like fire extinguisher refilling near me ensures that both portable and fixed fire safety systems are ready to operate when needed.

6. Safety Harnesses and Fall Protection

Falls are one of the leading causes of injuries in construction sites. Safety harnesses, lifelines, guardrails, and safety nets are essential for workers operating at heights. Proper training on how to wear and use fall protection equipment can prevent severe accidents. Employers should also inspect harnesses for wear and tear, replacing any damaged gear immediately.

7. Machine Safety Guards

Industrial machinery can be extremely dangerous without proper safety guards. Equipment should have guards on moving parts, emergency stop buttons, and clear operating instructions. Regular maintenance and inspections help prevent mechanical failures that could lead to injuries.

8. Electrical Safety Equipment

Electrical hazards are common in factories and construction sites. Insulated gloves, rubber mats, circuit breakers, and proper grounding are critical components for electrical safety. Workers should be trained to recognize hazards such as exposed wires, overloaded circuits, and faulty equipment. Maintaining fire extinguishers, especially CO2 types, is important because they are specifically effective against electrical fires.

9. Chemical Safety and Storage

Many factories deal with hazardous chemicals. Proper storage, labeling, and handling procedures reduce the risk of accidents. Safety data sheets (SDS) should be accessible to all employees, and spill kits should be available for emergencies. Workers should always use gloves, masks, and eye protection when handling chemicals.

10. Regular Safety Audits and Training

Having all the equipment is not enough; employees must be trained to use it effectively. Regular safety drills, equipment training, and emergency response sessions are essential. Periodic safety audits help identify risks, ensure compliance, and improve overall workplace safety.

During audits, check the status of fire extinguishers and related services. Using a fire extinguisher refilling shop near me ensures all units are in working condition. Keeping a record of refills, inspections, and maintenance strengthens safety management and compliance with local regulations.

Conclusion

Creating a safe working environment in factories and construction sites requires a comprehensive approach. A detailed checklist covering fire safety, personal protective equipment, emergency systems, electrical and chemical safety, and regular training is vital. Maintaining fire extinguishers through services like fire extinguisher refilling service near me, CO2 fire extinguisher refilling near me, and visiting a fire extinguisher refilling shop near me ensures that fire safety is never compromised.

By systematically following this safety equipment checklist, employers can protect workers, reduce accidents, and maintain a compliant and secure workplace. Safety is not just a legal requirement—it is a responsibility that saves lives and fosters a culture of care and professionalism.

Also Read: