Industrial work environments are inherently risky. Factories, construction sites, chemical plants, and other industrial areas often expose workers to fire hazards due to high temperatures, flammable chemicals, and heavy machinery. Ensuring worker safety is not just a regulatory requirement but a moral responsibility. One of the most crucial steps in protecting industrial workers is providing the right fire safety gear. This article explores the importance, types, and benefits of fire safety equipment, helping employers and workers understand how to minimize risks effectively.

Understanding the Importance of Fire Safety Equipment

Fire safety equipment is designed to prevent, control, or extinguish fires while protecting human life. In industrial settings, the consequences of fire can be catastrophic, leading to injuries, fatalities, and massive property damage. Workers are at higher risk because they operate machinery, handle flammable materials, and often work in confined spaces.

Using proper fire safety gear reduces the risk of burns, inhalation injuries, and fatalities. It also ensures compliance with workplace safety regulations set by organizations such as OSHA (Occupational Safety and Health Administration) or local regulatory authorities in Pakistan. Employers investing in high-quality fire safety equipment not only safeguard their employees but also protect their business from financial losses caused by fire accidents.

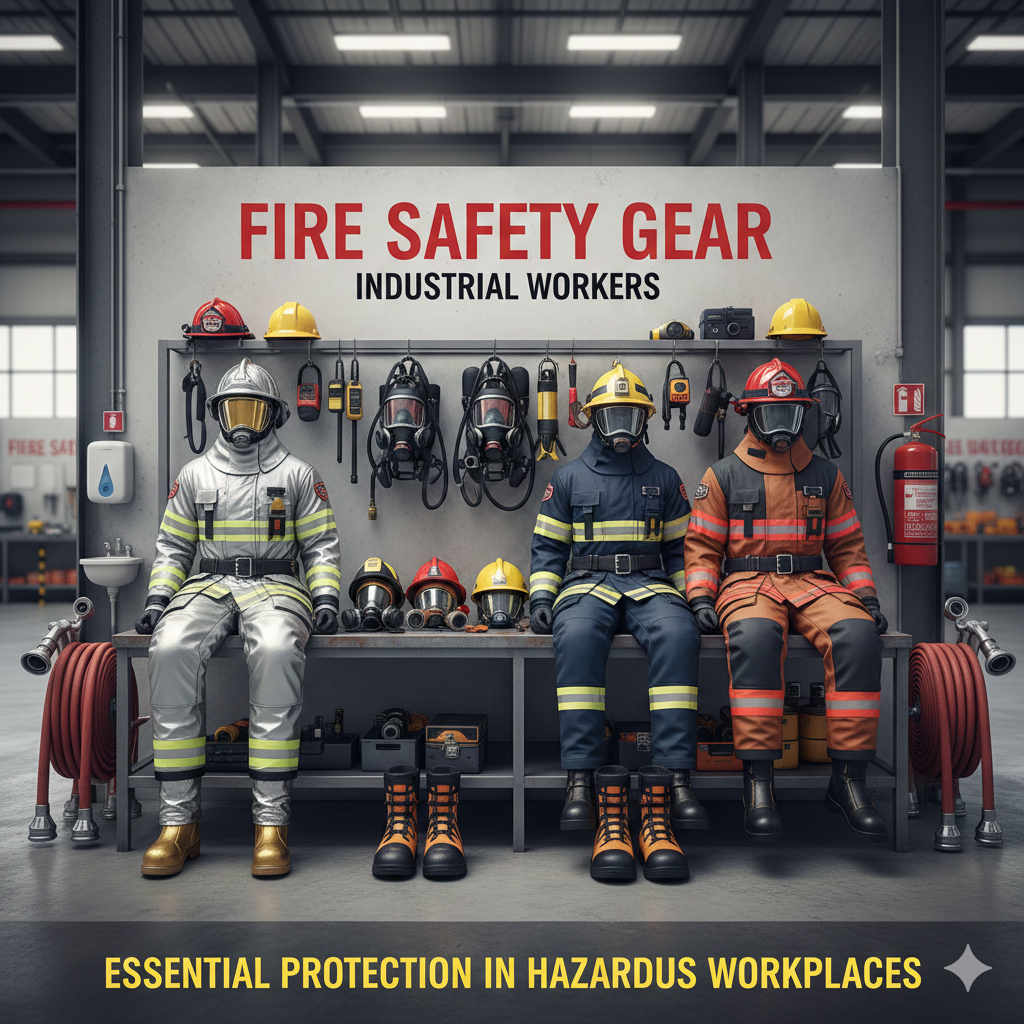

Essential Fire Safety Gear for Industrial Workers

Industrial fire safety involves a combination of personal protective equipment (PPE), fire suppression tools, and safety protocols. Each piece of equipment plays a unique role in ensuring worker safety.

1. Fire-Resistant Clothing

Fire-resistant clothing is a fundamental component of industrial fire safety gear. These garments are made from materials that resist ignition and prevent burns from flames or heat. Common examples include fire-retardant jackets, pants, and coveralls.

Fire-resistant clothing works by slowing down the burning process, giving workers more time to escape or respond to a fire. In industries like welding, oil and gas, and chemical manufacturing, wearing fire-resistant clothing can mean the difference between minor injuries and severe burns.

2. Fire-Resistant Gloves

Hands are often the most exposed body part during industrial work. Fire-resistant gloves protect workers from burns and heat-related injuries. These gloves are typically made from materials such as leather, Kevlar, or Nomex, which provide heat resistance and durability.

Choosing the right gloves depends on the type of work. For instance, welders need thick, heat-resistant gloves, while workers handling chemicals may require gloves that also offer chemical resistance.

3. Helmets and Fire-Resistant Headgear

Head injuries are another serious risk in industrial settings. Fire-resistant helmets provide dual protection: they shield the head from falling objects and protect against heat or flames. Some helmets come with visors to protect the face and eyes from sparks, chemical splashes, or intense heat.

High-quality helmets are lightweight and adjustable, ensuring comfort for workers who need to wear them for long hours. Industrial workers in construction, metal fabrication, and petrochemical plants should always wear certified helmets that meet fire safety standards.

4. Eye and Face Protection

Flames, sparks, and molten particles pose a significant risk to the eyes. Safety goggles, face shields, and fire-resistant visors are essential fire safety equipment that prevents eye injuries.

Face shields are particularly useful for welders, metal workers, and chemical plant employees. They cover the entire face, reducing the risk of burns and debris-related injuries. Workers should ensure that their eye and face protection is resistant to high temperatures and impact.

5. Respiratory Protection

Smoke inhalation is one of the leading causes of death in fire accidents. Fire safety gear includes respirators and breathing apparatus that allow workers to operate safely in smoke-filled or hazardous environments.

Industrial workers handling chemicals or working in areas prone to fire outbreaks must use self-contained breathing apparatus (SCBA) or masks designed to filter out toxic gases. Proper training on using respiratory equipment is crucial to ensure effectiveness during emergencies.

6. Fire Boots and Protective Footwear

Foot injuries are common in industrial environments, especially during fire emergencies. Fire-resistant boots protect workers from heat, flames, and falling objects. These boots often feature steel toes, slip-resistant soles, and insulating materials to protect against extreme temperatures.

Choosing the right footwear ensures that workers maintain mobility during emergencies while minimizing the risk of burns or injuries. Fire safety boots are essential for construction workers, factory staff, and oil refinery employees.

7. Fire Extinguishers and Portable Suppression Tools

While personal protective equipment protects individuals, fire suppression tools help control and extinguish fires before they spread. Fire extinguishers are a critical component of industrial fire safety equipment.

Different types of fire extinguishers target specific fire classes, including electrical fires, flammable liquids, and combustible metals. Employers must provide accessible and well-maintained fire extinguishers throughout the workplace. Workers should be trained on their correct usage to respond quickly during emergencies.

8. Fire Blankets and Emergency Escape Equipment

Fire blankets are simple yet effective tools for smothering flames on a person or equipment. Industrial settings, particularly laboratories and chemical plants, benefit from having fire blankets strategically placed for quick access.

In addition to fire blankets, emergency escape equipment like ladders, exit signs, and fire evacuation routes is essential. Workers must know the location of all escape routes and practice regular fire drills to ensure readiness in case of an actual fire.

9. Heat and Flame Detection Systems

Advanced fire safety in industrial workplaces often involves heat and flame detection systems. These systems detect temperature spikes or flames early, triggering alarms and automated fire suppression measures.

Industrial workers rely on these systems to provide early warnings, allowing them to evacuate safely and prevent fire escalation. Integrating detection systems with personal fire safety gear enhances overall workplace safety.

Maintenance and Regular Inspection of Fire Safety Equipment

Having fire safety equipment is only effective if it is well-maintained. Industrial workplaces must establish protocols for regular inspection, maintenance, and replacement of fire safety gear.

Clothing, gloves, helmets, and boots should be checked for wear and tear, heat damage, or contamination. Fire extinguishers must be serviced periodically, and batteries in detection systems should be replaced on schedule. Ensuring that all equipment is functional guarantees maximum protection for workers in emergencies.

Training and Awareness for Industrial Workers

Equipping workers with fire safety gear is only half the solution. Proper training and awareness are equally important. Industrial workers must understand how to use their fire safety equipment, recognize fire hazards, and respond effectively during emergencies.

Training programs should include:

-

How to use fire extinguishers and fire blankets

-

Proper donning of fire-resistant clothing and helmets

-

Evacuation procedures and emergency exits

-

Use of respiratory protection in smoke-filled environments

-

Regular fire drills to simulate real-life scenarios

Well-trained workers are more confident, respond faster, and minimize injuries during fire incidents.

Choosing the Right Fire Safety Equipment Supplier

Selecting a reliable supplier for industrial fire safety equipment is crucial. The quality, certifications, and durability of the equipment directly impact worker safety.

Employers should look for suppliers who provide products that meet international standards, offer warranties, and provide guidance on proper use. Fire safety equipment from certified suppliers ensures compliance with safety regulations and long-term protection for workers.

The Role of Technology in Fire Safety

Modern industrial fire safety has benefited significantly from technological advancements. Smart fire detection systems, wearable sensors, and fire-resistant materials have made workplaces safer than ever before.

Wearable sensors can monitor worker location and exposure to heat or smoke, alerting them and safety teams to potential danger. Advanced fire-resistant materials used in clothing and gloves enhance protection without compromising comfort.

By integrating technology with traditional fire safety equipment, industrial workplaces can significantly reduce fire-related risks.

Conclusion: Prioritizing Worker Safety Through Fire Safety Equipment

Fire safety gear is not optional for industrial workers; it is a necessity. Properly selected, maintained, and used fire safety equipment can save lives, reduce injuries, and minimize property damage.

Employers must invest in high-quality fire-resistant clothing, helmets, gloves, boots, respiratory protection, fire extinguishers, and emergency tools. Coupled with regular training, inspection, and the integration of technology, these measures create a comprehensive safety system.

Prioritizing fire safety in industrial workplaces not only ensures compliance with regulations but also demonstrates a commitment to the well-being of workers. In industries where fire hazards are constant, nothing is more valuable than the lives of trained, well-protected employees.

Industrial safety is a shared responsibility. Employers, safety officers, and workers must work together to create a culture where fire safety equipment is used effectively, risks are minimized, and everyone returns home safely at the end of the day.

Also Read: