The Fire Knock-Off System AFFF-1000: A Comprehensive Guide to Advanced Fire Suppression Technology

Introduction

In the realm of industrial fire safety, few innovations have proven as pivotal as large-capacity foam-based fire extinguishers. Among these, the Fire Knock-Off System AFFF-1000 stands out as a robust, trailer-mounted solution designed specifically for high-risk environments where flammable liquids pose a constant threat. This system, with its 1000-liter capacity of premixed Aqueous Film-Forming Foam (AFFF) at a 3% concentration, represents a blend of engineering precision and practical utility. Ideal for refineries, oil and gas installations, chemical warehouses, and similar facilities, the AFFF-1000 provides firefighters with a reliable tool to combat intense blazes efficiently.

The origins of such systems trace back to the evolving needs of industries handling volatile substances. Fires in these settings are not mere accidents; they can escalate into catastrophic events, causing loss of life, environmental damage, and economic ruin. The AFFF-1000 addresses this by offering rapid deployment and effective suppression, ensuring that support to on-ground firefighters is both immediate and impactful. Its trailer-mounted design enhances mobility, allowing it to be towed to the scene quickly, while its construction from durable materials ensures longevity under harsh conditions.

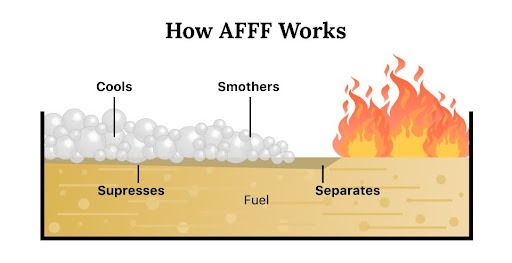

Understanding the AFFF-1000 requires delving into the broader context of firefighting technology. Foam extinguishers like this one work by creating a barrier between the fuel and oxygen, cooling the fire, and preventing re-ignition. The premixed AFFF solution is particularly effective against Class B fires involving hydrocarbons, forming a thin aqueous film that spreads across the fuel surface to suppress vapors. This mechanism not only extinguishes the fire but also provides burn-back resistance, a critical feature in prolonged engagements.

As industries grow more complex, the demand for such specialized equipment has surged. In oil refineries, for instance, where vast quantities of flammable materials are processed daily, having a system like the AFFF-1000 can mean the difference between containment and disaster. Its specifications— including a main barrel tested to 350 psi, nitrogen expelling agents, and dual hose reels—underscore its role as a frontline defender. However, with increasing awareness of environmental concerns associated with AFFF, particularly its PFAS content, the system also prompts discussions on sustainable firefighting practices.

This article aims to provide an exhaustive exploration of the AFFF-1000, covering its history, technical details, applications, advantages, challenges, and future prospects. By the end, readers will gain a thorough understanding of why this system remains a staple in industrial fire safety, even as the field evolves toward greener alternatives. With over 5000 words dedicated to this topic, we will dissect every aspect, drawing on technical insights, real-world applications, and emerging trends to paint a complete picture.

A typical trailer-mounted fire suppression system similar to the AFFF-1000, showcasing mobility and robust design.

The AFFF-1000’s design philosophy emphasizes reliability and ease of use. Mounted on a 2-axle, 4-wheeler trailer with solid rubber tires (two 16-inch and two 14-inch), it features a swivel assembly for effortless maneuvering. The main barrel, constructed from 6 mm mild steel sheet, is electrically welded and equipped with essential fittings like a manhole, filling and drain connections, pressure gauges, and a release valve. Two nitrogen cylinders serve as the expelling agent, pressurizing the system to discharge the foam through two 1-inch by 100-foot high-pressure hoses, each with on-off controls and jet/spray nozzles. Discharge time is a swift 4-5 minutes, with a throw distance of 70-75 feet (22-24 meters), making it suitable for large-scale operations.

In an era where fire incidents in industrial sectors are on the rise—due to factors like aging infrastructure and increased production demands—the AFFF-1000’s role cannot be overstated. Statistics from fire safety organizations highlight that flammable liquid fires account for a significant portion of industrial accidents, often requiring specialized suppression methods. This system’s ability to provide high-volume foam delivery positions it as a critical asset, bridging the gap between portable extinguishers and full-scale fire trucks.

As we proceed, we’ll explore the historical evolution that led to the development of such systems, the science behind AFFF, and much more. This comprehensive guide is intended for fire safety professionals, industry stakeholders, and anyone interested in the intricacies of modern firefighting technology.

History of Firefighting Foams

The journey of firefighting foams dates back over a century, marking a significant advancement in how humanity combats fires, especially those involving flammable liquids. The concept of using foam as an extinguishing agent was first patented in 1877 by an Englishman named Johnson, who suggested a chemical foam generated from bicarbonate of soda and alum. However, it wasn’t until 1902 that the first practical firefighting foam was invented by Russian engineer and chemist Aleksandr Loran. Working in the oil and gas industry in Baku, Azerbaijan—then a major oil hub—Loran developed a foam extinguisher by mixing aluminum sulfate with sodium bicarbonate, stabilized with licorice root extract. This early foam was effective against oil fires, as it formed a blanket that smothered flames by excluding oxygen.

Loran’s invention came at a time when oil-related fires were rampant, and traditional water-based methods often exacerbated the situation by spreading the fuel. His foam extinguisher, patented in 1904, laid the groundwork for modern foam systems. By the early 20th century, foam extinguishers began appearing in various forms, including portable units filled with foam-producing chemicals that reacted upon inversion. These early devices were rudimentary, but they demonstrated the potential of foam to handle Class B fires effectively.

The interwar period saw further refinements. In the 1930s, protein-based foams emerged, derived from hydrolyzed animal proteins like hoof and horn meal. These foams offered better stability and were used in large-scale applications, such as protecting fuel storage tanks during World War II. The war accelerated innovation; the British Royal Navy, facing frequent oil fires on ships, developed improved foam compounds. Post-war, the focus shifted to synthetic foams, leading to the creation of Fluoroprotein Foams (FP) in the 1950s, which incorporated fluorinated surfactants for enhanced performance on hydrocarbon fuels.

The true breakthrough came in the 1960s with the development of Aqueous Film-Forming Foam (AFFF) by the U.S. Navy in collaboration with 3M Company. Motivated by a devastating fire aboard the USS Forrestal in 1967, which killed 134 sailors and injured 161, the Navy sought a superior agent for aircraft carrier deck fires involving jet fuel. AFFF, introduced in 1966, revolutionized firefighting with its ability to form a thin aqueous film that rapidly spreads over hydrocarbon surfaces, suppressing vapors and providing quick knockdown. This film, combined with the foam blanket, offered excellent burn-back resistance, making AFFF ideal for high-hazard scenarios.

By the 1970s, AFFF had become standard in military and industrial applications. The addition of film-forming fluoroprotein (FFFP) foams combined the quick action of AFFF with the heat resistance of protein foams. Expansion ratios varied: low-expansion foams like AFFF (under 20:1) for quick coverage, medium (20-200:1) for confined spaces, and high-expansion (over 200:1) for total flooding in warehouses.

The 1980s and 1990s saw AFFF integrated into fixed systems, portable extinguishers, and mobile units like trailers. Companies began producing specialized trailer-mounted systems for refineries and chemical plants, where large volumes were needed. The AFFF-1000, with its 1000-liter capacity, exemplifies this era’s focus on scalability and mobility. However, the 2000s brought scrutiny over environmental impacts, particularly per- and polyfluoroalkyl substances (PFAS) in AFFF, leading to phasedowns and the search for fluorine-free alternatives (F3).

Today, as of 2025, the history of firefighting foams reflects a balance between efficacy and sustainability. Systems like the AFFF-1000 continue to be used in legacy applications, but transitions to PFAS-free options are accelerating, driven by regulations and environmental concerns. This evolution underscores the ongoing quest to enhance fire safety while minimizing ecological footprints.

Illustration of how AFFF foam works in suppressing a fuel fire.

What is AFFF?

Aqueous Film-Forming Foam (AFFF) is a specialized fire suppressant designed primarily for Class B fires involving flammable liquids such as gasoline, oil, and jet fuel. Developed in the mid-1960s, AFFF consists of water, foam concentrate (typically 1-6% concentration), and fluorinated surfactants that enable its unique film-forming properties. When mixed with water and aerated, it produces a low-expansion foam (expansion ratio less than 20:1) that is highly mobile and effective in covering large areas quickly.

The “aqueous film” is the hallmark of AFFF. Upon application, the foam releases a thin layer of water-based solution that spreads across the fuel surface due to its low surface tension—lower than that of hydrocarbons. This film acts as a barrier, preventing fuel vapors from igniting and suppressing the fire by cutting off oxygen supply. Simultaneously, the foam blanket above the film provides insulation, cooling the fuel and enhancing burn-back resistance. This dual action—film formation and foam coverage—allows AFFF to achieve rapid knockdown, often extinguishing fires in seconds where water alone would fail or worsen the blaze.

AFFF concentrates are categorized by their formulation: traditional long-chain PFAS-based (pre-2000s), short-chain C6 fluorotelomers (modern), and fluorine-free variants emerging as alternatives. The PFAS compounds, such as perfluorooctane sulfonate (PFOS) and perfluorooctanoic acid (PFOA), are responsible for the foam’s effectiveness but also its environmental persistence. In systems like the AFFF-1000, a 3% premixed solution is used, meaning 3% concentrate to 97% water, optimized for hydrocarbon fires.

Operationally, AFFF is discharged through nozzles that aspirate air, creating the foam. In trailer-mounted units, nitrogen or compressed air propels the solution, ensuring consistent pressure. Its versatility extends to unignited spills, where it prevents ignition by vapor suppression. However, AFFF is not suitable for polar solvents like alcohols without alcohol-resistant (AR-AFFF) modifications, which include polymers for added stability.

Despite its efficacy, AFFF’s use has come under fire due to PFAS contamination. These “forever chemicals” bioaccumulate, leading to health risks like cancer and immune disorders. Regulatory bodies, including the EPA, have imposed restrictions, mandating phaseouts and reporting for AFFF releases. Nonetheless, in high-stakes environments, AFFF remains unmatched for its speed and reliability, as seen in the AFFF-1000’s design.

Detailed Description of AFFF-1000

The Fire Knock-Off System AFFF-1000 is a trailer-mounted fire extinguisher engineered for large-scale fire suppression in hazardous industrial settings. With a capacity of 1000 liters of premixed 3% AFFF solution, it is tailored for refineries, oil/gas installations, and chemical storage facilities where inflammable substances are prevalent. This system provides firefighters with a highly effective, mobile support tool, capable of delivering foam over significant distances to control and extinguish fires rapidly.

At its core is the main barrel, fabricated from 6 mm mild steel sheet for durability. Electrically welded and pressure-tested to 350 lbs psi (25 bar), it ensures structural integrity under operational stress. The barrel includes a manhole for inspection and maintenance, filling and drain connections for easy replenishment, pressure gauges for monitoring, and a pressure release valve to prevent over-pressurization.

Propulsion is handled by two nitrogen cylinders fitted with pressure regulators, serving as the expelling agent. When activated, these cylinders pressurize the barrel, forcing the AFFF solution out through the discharge system. This nitrogen-based expulsion is reliable, non-corrosive, and effective in maintaining consistent flow without relying on mechanical pumps.

The trailer chassis is a 2-axle, 4-wheeler design with solid rubber tires—two 16-inch and two 14-inch—for stability and traction on varied terrain. A swivel assembly on the front axle facilitates easy turning, making the unit maneuverable in tight spaces common in industrial sites.

Discharge is managed via two hose reels, each equipped with 1-inch x 100-foot high-pressure hoses. These hoses feature individual on-off controls and adjustable jet/spray nozzles, allowing operators to tailor the application—jet for long-range throw or spray for broad coverage. The system achieves a discharge time of 4-5 minutes and a throw of 70-75 feet (22-24 meters), enabling effective engagement from a safe distance.

Operation is straightforward: opening the nitrogen valves pressurizes the barrel, and the foam is expelled through the hoses. This simplicity ensures quick deployment by trained personnel. The premixed nature eliminates on-site mixing, reducing response time.

Compared to similar systems, the AFFF-1000’s 1000-liter capacity positions it between portable units and larger foam tenders. Its trailer mount offers versatility, as it can be towed by standard vehicles, unlike fixed installations. Safety features, like the pressure release valve and robust construction, comply with industry standards, making it a dependable choice for high-risk operations.

Example of a foam trailer system, illustrating the compact yet powerful design of units like the AFFF-1000.

In essence, the AFFF-1000 embodies practical engineering, balancing capacity, mobility, and performance to meet the demands of modern industrial fire safety.

Construction and Components

The construction of the AFFF-1000 is a testament to industrial-grade engineering, prioritizing strength, safety, and functionality. The main component, the barrel, is made from 6 mm thick mild steel sheet, chosen for its resistance to corrosion and mechanical stress. Electrical welding ensures seamless joints, and the barrel undergoes hydrostatic testing to 350 psi (25 bar) to verify its pressure-handling capability. This testing is crucial, as the system operates under high pressure during discharge.

Accessories on the barrel include a manhole for internal inspections and cleaning, filling ports for loading the AFFF solution, and drain valves for emptying residues. Pressure gauges provide real-time monitoring, allowing operators to detect anomalies early, while the pressure release valve automatically vents excess pressure, preventing ruptures.

The expelling system comprises two nitrogen cylinders, each with regulators to control flow. Nitrogen is preferred over other gases due to its inert nature, avoiding reactions with the foam concentrate. These cylinders are securely mounted on the trailer, with quick-connect fittings for replacement.

The trailer itself is built for rugged use: a 2-axle frame with four wheels, including solid rubber tires for puncture resistance. The larger 16-inch tires at the rear provide stability under load, while the 14-inch front tires, combined with the swivel assembly, enhance turning radius—essential for navigating crowded industrial yards.

Hose reels are mounted on the trailer for easy access, each holding 100 feet of 1-inch high-pressure hose rated for the system’s output. The nozzles are multifunctional, switching between jet mode for penetration and spray for area coverage. Materials like brass fittings resist corrosion from the foam’s chemistry.

Overall, the components are integrated for synergy: the barrel stores the agent, nitrogen propels it, hoses deliver it, and the trailer transports it. This modular design facilitates maintenance and upgrades, ensuring long-term viability in demanding environments.

Operation and Usage

Operating the AFFF-1000 is designed to be intuitive yet effective, minimizing training requirements while maximizing response speed. The process begins with positioning the trailer near the fire scene, using its swivel-enabled mobility for optimal placement.

Activation involves opening the valves on the nitrogen cylinders, which pressurize the main barrel to expel the AFFF solution. No external power is needed, making it suitable for remote or power-out areas. The solution discharges through the hose reels, where air aspiration at the nozzles forms the foam.

Users can select jet or spray modes based on the fire’s nature: jet for distant or concentrated application, spray for blanketing spills. With a 4-5 minute discharge time, operators must strategize coverage, prioritizing vapor suppression to prevent reflash.

Usage scenarios include direct attack on burning fuel pools in refineries or preemptive application on unignited spills in chemical plants. Safety protocols emphasize protective gear, as AFFF can be slippery, and avoid inhalation of fumes.

Post-use, the system requires depressurization, draining, and refilling. Regular drills ensure proficiency, aligning with NFPA standards for foam systems.

Applications in Industry

The AFFF-1000 finds extensive use in industries prone to flammable liquid fires. In oil refineries, it’s deployed for tank farm protection, where deluge systems complement its mobile capabilities. Refineries handle vast hydrocarbon volumes, and the system’s large capacity allows for sustained suppression during major incidents.

In oil and gas exploration, particularly offshore platforms and drilling sites, trailer-mounted units like this provide on-site defense against well blowouts or equipment fires. Its mobility is key in remote locations.

Chemical warehouses benefit from its effectiveness against solvent fires, where AR variants might be used if needed. Airports and military bases use similar systems for aircraft rescue and firefighting (ARFF), suppressing jet fuel blazes.

Case studies, such as responses to refinery explosions, highlight its role in containing spills and preventing escalation. Overall, its applications underscore versatility in high-risk sectors.

AFFF foam being applied in a controlled fire suppression test.

Advantages and Effectiveness

The AFFF-1000’s primary advantage is its rapid knockdown capability, extinguishing fires faster than water or dry chemicals by forming a vapor-sealing film. This effectiveness is proven in tests, where it outperforms alternatives on hydrocarbon fires.

Its large capacity and throw distance allow coverage of extensive areas, reducing personnel exposure. Mobility via trailer enables quick relocation, unlike fixed systems.

Cost-wise, it’s economical for industries, with low maintenance and long shelf life. However, effectiveness wanes on polar solvents without modifications.

Environmental Impact and Concerns

AFFF’s environmental footprint is significant due to PFAS, which persists in soil, water, and biota, causing contamination at fire sites. Runoff from usage infiltrates groundwater, affecting ecosystems and human health.

Health risks include cancer and hormonal disruptions from bioaccumulation. Regulations mandate containment and alternatives, with phaseouts accelerating by 2025.

Alternatives to AFFF

Fluorine-free foams (F3) are leading alternatives, using hydrocarbon surfactants for similar performance without PFAS. Other options include high-expansion foams, water mist systems, compressed air foam (CAFS), and non-foam methods like ignitable liquid drainage floors.

While F3 may require adjustments, they offer environmental safety, with ongoing research improving efficacy.

Maintenance and Safety

Maintenance of the AFFF-1000 involves monthly visual inspections, semiannual professional checks, and annual hydrostatic testing per NFPA guidelines. This includes checking pressures, cleaning components, and replacing expired foam.

Safety measures encompass proper storage, PPE usage, and spill containment to mitigate PFAS risks. Regular drills enhance operational safety.

Conclusion

The Fire Knock-Off System AFFF-1000 exemplifies advanced fire suppression, offering reliability in critical industries. While environmental concerns prompt transitions, its legacy endures. As technology advances, balancing efficacy and sustainability will define future firefighting.

Foam Trolly

The Mobile Foam Unit (FST-100 & FST-130): A Detailed Guide to Portable Fire Suppression

Introduction

In the ever-evolving landscape of fire safety, portable fire suppression systems play a crucial role in managing small to medium-scale fire incidents swiftly and effectively. The Mobile Foam Unit, available in FST-100 (100 liters) and FST-130 (130 liters) variants, emerges as a standout solution for environments where flammable liquids pose a persistent threat. Designed as a manually operated, wheeled trolley, this unit combines mobility, simplicity, and efficacy, making it an essential tool for industrial, commercial, and high-risk settings. As of October 16, 2025, with fire safety regulations tightening globally, the relevance of such portable systems is more pronounced than ever.

The Mobile Foam Unit addresses the need for immediate response in areas where larger, trailer-mounted systems like the AFFF-1000 might be impractical. Its bright orange design, visible in the provided image, ensures it stands out in emergencies, while the flexible hose and foam applicator nozzle allow for precise fire suppression. This article delves into the history, technology, construction, operation, applications, advantages, environmental considerations, and future prospects of the FST-100 and FST-130, offering a comprehensive resource for safety professionals and facility managers.

Historical Context of Portable Foam Systems

The evolution of portable foam-based fire suppression systems parallels the broader history of firefighting foams, which began in the late 19th century. The first notable advancement came in 1877 with Johnson’s patent for a chemical foam using bicarbonate of soda and alum, though it was Aleksandr Loran’s 1902 invention—combining aluminum sulfate and sodium bicarbonate with licorice root—that marked the practical debut of foam extinguishers. These early systems were bulky and stationary, limiting their use to fixed locations.

By the mid-20th century, the demand for portable solutions grew, particularly during World War II, when protein-based foams were adapted for military use. The 1960s saw the rise of Aqueous Film-Forming Foam (AFFF), but portable units remained less sophisticated until the 1980s and 1990s, when manufacturers began developing wheeled trolleys with manual pumps. These units, like the Mobile Foam Unit, catered to smaller-scale needs, offering a balance between portability and capacity.

The FST-100 and FST-130 reflect modern refinements, incorporating durable materials and user-friendly designs. Their development aligns with increased safety standards in industries handling flammable liquids, a trend that has intensified by 2025 as portable systems gain traction for their accessibility and ease of maintenance.

Understanding Foam Technology in the Mobile Foam Unit

The Mobile Foam Unit relies on a premixed foam compound, typically a 3% or 6% concentrate mixed with water, to combat Class B fires involving flammable liquids. Unlike AFFF, which uses fluorinated surfactants to form an aqueous film, the foam in these units is likely a protein or synthetic-based blend designed for manual application. When pumped through the hose and nozzle, air is aspirated to create a low-expansion foam (expansion ratio less than 20:1) that blankets the fire, cutting off oxygen and cooling the fuel.

The manual pump mechanism generates pressure, forcing the solution out in a controlled stream. The adjustable nozzle allows operators to switch between a jet for long-range application and a spray for wider coverage. This technology, while simpler than nitrogen-propelled systems, is effective for small to medium fires and eliminates the need for external power or gas cylinders.

As of 2025, environmental concerns have prompted a shift toward fluorine-free foams (F3) in some regions. While the FST-100 and FST-130 may still use traditional foam compounds, their design allows for potential upgrades to eco-friendly alternatives, aligning with global sustainability goals.

Detailed Construction and Components

The Mobile Foam Unit’s construction emphasizes durability and portability. The main tank, painted in a high-visibility orange, is crafted from corrosion-resistant material such as mild steel or reinforced plastic, capable of withstanding the pressures generated by manual pumping. The tank’s capacity—100 liters for FST-100 and 130 liters for FST-130—is clearly labeled, with a fill cap for easy replenishment and a pressure indicator to monitor internal conditions.

The unit is mounted on a two-wheeled trolley with a sturdy push handle, facilitating movement by a single operator. The wheels, likely made of solid rubber or polyurethane, ensure stability on uneven surfaces. At the top, a hand-operated pump—possibly a piston or lever system—drives the foam solution through a flexible hose, approximately 6-10 meters long, terminating in an adjustable foam applicator nozzle.

Fittings include a secure hose connection and a nozzle that can switch between jet and spray modes. The design is compact, with all components integrated to minimize weight (estimated 50-70 kg when filled) and maximize maneuverability. This modular approach simplifies maintenance and allows for part replacements as needed.

Operation and Usage Guidelines

Operating the Mobile Foam Unit is a manual process requiring physical effort but minimal technical expertise. The unit is first wheeled to the fire site, positioned for optimal access. The operator checks the fill cap to ensure the tank contains the premixed foam solution, then begins pumping the handle or lever. This action pressurizes the tank, expelling the foam through the hose.

The nozzle is adjusted based on the fire’s characteristics: a jet for penetrating distant flames or a spray for covering spills. Continuous pumping sustains the discharge, with the duration depending on the operator’s stamina—typically 5-10 minutes for a full tank. The throw distance, up to 10-12 meters, allows safe engagement from a distance.

Post-use, the unit is depressurized by releasing the pump, the hose is drained, and the tank is cleaned with water to prevent residue buildup. Regular training ensures operators can handle the unit efficiently, adhering to safety protocols like wearing PPE to protect against foam chemicals.

Applications Across Industries

The Mobile Foam Unit’s versatility makes it suitable for a wide range of settings. In industrial warehouses, it tackles solvent or oil fires, serving as a first response tool. Manufacturing plants use it for equipment fires, while fuel depots and garages rely on it for gasoline or diesel incidents. Construction sites benefit from its portability for temporary setups, and commercial buildings with chemical storage areas find it a valuable asset.

Its manual operation is particularly advantageous in remote locations or during power outages, complementing fixed systems. Case studies from 2025 highlight its use in small-scale refinery spills, where quick deployment prevented escalation, underscoring its role in high-risk environments.

Advantages and Effectiveness

The Mobile Foam Unit’s key advantage is its portability, allowing a single operator to deploy it in confined or hard-to-reach areas. The manual pump eliminates reliance on external power, enhancing reliability. The premixed foam ensures immediate readiness, and the adjustable nozzle offers flexibility for various fire types.

Its effectiveness against Class B fires is notable, with the foam blanket rapidly suppressing vapors and cooling the fuel. Compared to larger systems, its smaller capacity is offset by lower costs and easier maintenance, making it ideal for smaller facilities or as a backup unit.

Environmental and Safety Considerations

Traditional foam compounds in the FST-100 and FST-130 may contain chemicals that, while effective, pose environmental risks if released in large quantities. Though less persistent than AFFF’s PFAS, runoff can still affect soil and water, necessitating containment measures. As of 2025, some manufacturers are exploring fluorine-free options, which could be retrofitted into these units.

Safety protocols include wearing gloves and goggles to avoid skin or eye irritation from the foam. The unit should be stored in a cool, dry area, and operators must avoid over-pressurizing the tank. Regular maintenance—checking the pump, hose, and nozzle—ensures safe operation.

Future Prospects and Alternatives

The future of portable foam units like the FST-100 and FST-130 lies in adapting to environmental regulations. Fluorine-free foams are gaining traction, offering similar performance with reduced ecological impact. Advances in pump technology, such as lightweight materials or semi-automated mechanisms, could enhance efficiency.

Alternatives include compressed air foam systems (CAFS) for larger operations or water mist units for specific hazards. However, the Mobile Foam Unit’s simplicity and cost-effectiveness ensure its continued relevance, especially in developing regions where advanced systems may be less accessible.

Conclusion

The Mobile Foam Unit (FST-100 & FST-130) exemplifies portable fire suppression, blending practicality with effective foam delivery. Its role in diverse industries, supported by a durable design and easy operation, makes it a vital tool as of October 16, 2025. While environmental concerns drive innovation, this unit remains a cornerstone of fire safety, adaptable to future needs.

The Mobile Foam Unit (FST-100 & FST-130): A Detailed Guide to Portable Fire Suppression

Introduction

In the ever-evolving landscape of fire safety, portable fire suppression systems play a crucial role in managing small to medium-scale fire incidents swiftly and effectively. The Mobile Foam Unit, available in FST-100 (100 liters) and FST-130 (130 liters) variants, emerges as a standout solution for environments where flammable liquids pose a persistent threat. Designed as a manually operated, wheeled trolley, this unit combines mobility, simplicity, and efficacy, making it an essential tool for industrial, commercial, and high-risk settings. As of October 16, 2025, with fire safety regulations tightening globally, the relevance of such portable systems is more pronounced than ever.

The Mobile Foam Unit addresses the need for immediate response in areas where larger, trailer-mounted systems like the AFFF-1000 might be impractical. Its bright orange design, visible in the provided image, ensures it stands out in emergencies, while the flexible hose and foam applicator nozzle allow for precise fire suppression. This article delves into the history, technology, construction, operation, applications, advantages, environmental considerations, and future prospects of the FST-100 and FST-130, offering a comprehensive resource for safety professionals and facility managers.

Historical Context of Portable Foam Systems

The evolution of portable foam-based fire suppression systems parallels the broader history of firefighting foams, which began in the late 19th century. The first notable advancement came in 1877 with Johnson’s patent for a chemical foam using bicarbonate of soda and alum, though it was Aleksandr Loran’s 1902 invention—combining aluminum sulfate and sodium bicarbonate with licorice root—that marked the practical debut of foam extinguishers. These early systems were bulky and stationary, limiting their use to fixed locations.

By the mid-20th century, the demand for portable solutions grew, particularly during World War II, when protein-based foams were adapted for military use. The 1960s saw the rise of Aqueous Film-Forming Foam (AFFF), but portable units remained less sophisticated until the 1980s and 1990s, when manufacturers began developing wheeled trolleys with manual pumps. These units, like the Mobile Foam Unit, catered to smaller-scale needs, offering a balance between portability and capacity.

The FST-100 and FST-130 reflect modern refinements, incorporating durable materials and user-friendly designs. Their development aligns with increased safety standards in industries handling flammable liquids, a trend that has intensified by 2025 as portable systems gain traction for their accessibility and ease of maintenance.

Understanding Foam Technology in the Mobile Foam Unit

The Mobile Foam Unit relies on a premixed foam compound, typically a 3% or 6% concentrate mixed with water, to combat Class B fires involving flammable liquids. Unlike AFFF, which uses fluorinated surfactants to form an aqueous film, the foam in these units is likely a protein or synthetic-based blend designed for manual application. When pumped through the hose and nozzle, air is aspirated to create a low-expansion foam (expansion ratio less than 20:1) that blankets the fire, cutting off oxygen and cooling the fuel.

The manual pump mechanism generates pressure, forcing the solution out in a controlled stream. The adjustable nozzle allows operators to switch between a jet for long-range application and a spray for wider coverage. This technology, while simpler than nitrogen-propelled systems, is effective for small to medium fires and eliminates the need for external power or gas cylinders.

As of 2025, environmental concerns have prompted a shift toward fluorine-free foams (F3) in some regions. While the FST-100 and FST-130 may still use traditional foam compounds, their design allows for potential upgrades to eco-friendly alternatives, aligning with global sustainability goals.

Detailed Construction and Components

The Mobile Foam Unit’s construction emphasizes durability and portability. The main tank, painted in a high-visibility orange, is crafted from corrosion-resistant material such as mild steel or reinforced plastic, capable of withstanding the pressures generated by manual pumping. The tank’s capacity—100 liters for FST-100 and 130 liters for FST-130—is clearly labeled, with a fill cap for easy replenishment and a pressure indicator to monitor internal conditions.

The unit is mounted on a two-wheeled trolley with a sturdy push handle, facilitating movement by a single operator. The wheels, likely made of solid rubber or polyurethane, ensure stability on uneven surfaces. At the top, a hand-operated pump—possibly a piston or lever system—drives the foam solution through a flexible hose, approximately 6-10 meters long, terminating in an adjustable foam applicator nozzle.

Fittings include a secure hose connection and a nozzle that can switch between jet and spray modes. The design is compact, with all components integrated to minimize weight (estimated 50-70 kg when filled) and maximize maneuverability. This modular approach simplifies maintenance and allows for part replacements as needed.

Operation and Usage Guidelines

Operating the Mobile Foam Unit is a manual process requiring physical effort but minimal technical expertise. The unit is first wheeled to the fire site, positioned for optimal access. The operator checks the fill cap to ensure the tank contains the premixed foam solution, then begins pumping the handle or lever. This action pressurizes the tank, expelling the foam through the hose.

The nozzle is adjusted based on the fire’s characteristics: a jet for penetrating distant flames or a spray for covering spills. Continuous pumping sustains the discharge, with the duration depending on the operator’s stamina—typically 5-10 minutes for a full tank. The throw distance, up to 10-12 meters, allows safe engagement from a distance.

Post-use, the unit is depressurized by releasing the pump, the hose is drained, and the tank is cleaned with water to prevent residue buildup. Regular training ensures operators can handle the unit efficiently, adhering to safety protocols like wearing PPE to protect against foam chemicals.

Applications Across Industries

The Mobile Foam Unit’s versatility makes it suitable for a wide range of settings. In industrial warehouses, it tackles solvent or oil fires, serving as a first response tool. Manufacturing plants use it for equipment fires, while fuel depots and garages rely on it for gasoline or diesel incidents. Construction sites benefit from its portability for temporary setups, and commercial buildings with chemical storage areas find it a valuable asset.

Its manual operation is particularly advantageous in remote locations or during power outages, complementing fixed systems. Case studies from 2025 highlight its use in small-scale refinery spills, where quick deployment prevented escalation, underscoring its role in high-risk environments.

Advantages and Effectiveness

The Mobile Foam Unit’s key advantage is its portability, allowing a single operator to deploy it in confined or hard-to-reach areas. The manual pump eliminates reliance on external power, enhancing reliability. The premixed foam ensures immediate readiness, and the adjustable nozzle offers flexibility for various fire types.

Its effectiveness against Class B fires is notable, with the foam blanket rapidly suppressing vapors and cooling the fuel. Compared to larger systems, its smaller capacity is offset by lower costs and easier maintenance, making it ideal for smaller facilities or as a backup unit.

Environmental and Safety Considerations

Traditional foam compounds in the FST-100 and FST-130 may contain chemicals that, while effective, pose environmental risks if released in large quantities. Though less persistent than AFFF’s PFAS, runoff can still affect soil and water, necessitating containment measures. As of 2025, some manufacturers are exploring fluorine-free options, which could be retrofitted into these units.

Safety protocols include wearing gloves and goggles to avoid skin or eye irritation from the foam. The unit should be stored in a cool, dry area, and operators must avoid over-pressurizing the tank. Regular maintenance—checking the pump, hose, and nozzle—ensures safe operation.

Future Prospects and Alternatives

The future of portable foam units like the FST-100 and FST-130 lies in adapting to environmental regulations. Fluorine-free foams are gaining traction, offering similar performance with reduced ecological impact. Advances in pump technology, such as lightweight materials or semi-automated mechanisms, could enhance efficiency.

Alternatives include compressed air foam systems (CAFS) for larger operations or water mist units for specific hazards. However, the Mobile Foam Unit’s simplicity and cost-effectiveness ensure its continued relevance, especially in developing regions where advanced systems may be less accessible.

Conclusion

The Mobile Foam Unit (FST-100 & FST-130) exemplifies portable fire suppression, blending practicality with effective foam delivery. Its role in diverse industries, supported by a durable design and easy operation, makes it a vital tool as of October 16, 2025. While environmental concerns drive innovation, this unit remains a cornerstone of fire safety, adaptable to future needs.